Expandable container houses are revolutionizing the modular housing industry by offering a versatile, cost-effective, and sustainable solution for residential, commercial, and emergency housing. These homes are engineered for quick deployment, portability, and durability, making them ideal for various applications, including tiny homes, portable offices, and off-grid living spaces.

At Sunfine, we take pride in our precision-driven production process, ensuring that every expandable prefab home meets the highest structural strength, insulation, and weather resistance standards. Below is an in-depth look at our manufacturing process, from raw material preparation to final packaging and delivery.

1. Material Cutting & Preparation for Expandable Container Houses

The first step in manufacturing an expandable container home is accurately cutting and preparing raw materials to ensure precise assembly.

🔹 Process:

✔ Cutting Q235B galvanized steel frames for superior strength

✔ Precision-cutting EPS insulation panels for efficient thermal performance

✔ Preparing high-strength hinges and locking mechanisms for smooth expansion

🔹 Quality Control:

✔ Ensuring each component meets design specifications

✔ Eliminating rough edges for seamless assembly

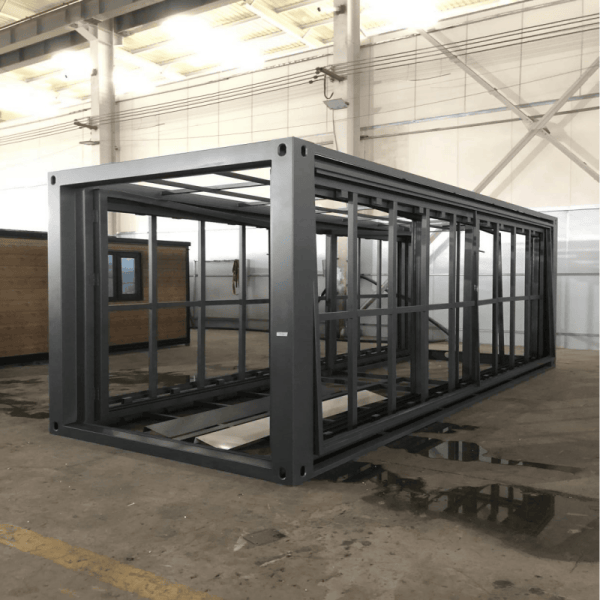

2. Welding & Frame Assembly for Expandable Container Houses

The steel framework of modular expandable homes must be structurally sound and weather-resistant. Welding plays a critical role in ensuring long-term durability.

🔹 Process:

✔ Using advanced welding technology to fuse high-strength steel components

✔ Reinforcing load-bearing sections for added stability

✔ Smoothing weld seams to prevent structural weak points

🔹 Quality Control:

✔ Inspected for uniformity and structural integrity

✔ Tested against industry-grade strength benchmarks

3. Expandable Structure & Wall Panel Assembly for Expandable Container Houses

Once the frame is complete, the expandable sections and modular walls are installed.

🔹 Process:

✔ Attaching folding side panels and expandable walls with reinforced hinges

✔ Installing thermal insulation layers for enhanced energy efficiency

✔ Incorporating structural reinforcements for wind and earthquake resistance

🔹 Why Sunfine’s Expandable Homes?

✔ Engineered to withstand Level 12 winds and Level 8 earthquakes

✔ Energy-efficient design reduces heating and cooling costs

4. Quality Inspection of Expandable Container Houses

Before moving to the next stage, every expandable prefab home undergoes a strict quality inspection to ensure structural safety and compliance.

🔹 Process:

✔ Load-bearing tests on roof and floor panels (standard capacity: 200kg/㎡)

✔ Ensuring smooth panel expansion and locking systems

✔ Verifying waterproofing & sealing of all joints

🔹 Global Certifications

✔ CE certification for European safety standards

✔ Fire-resistant material certification

✔ Structural calculation reports for engineering verification

5. Anti-Corrosion Coating for Expandable Container Houses

To enhance durability and longevity, all steel components are coated with high-performance protective layers.

🔹 Process:

✔ Rust-resistant coatings applied to galvanized steel

✔ Electrostatic powder coating for superior weather protection

✔ Heat treatment for color retention and scratch resistance

🔹 Advantages:

✔ Ensures a minimum 15-year lifespan with proper maintenance

✔ Prevents corrosion, rust, and UV damage

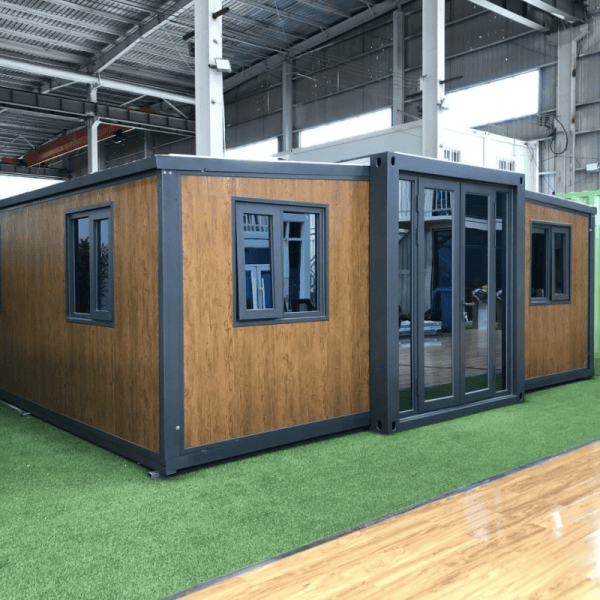

6. Interior Installation & Utility Systems for Expandable Container Houses

At this stage, the interior features and electrical systems are installed, making the expandable home fully functional.

🔹 Process:

✔ Installing kitchen, bathroom, electrical wiring, and plumbing

✔ Adding flooring, doors, and energy-efficient windows

✔ Integrating LED lighting and smart control systems (optional)

🔹 Why Choose Sunfine?

✔ Pre-installed electrical & plumbing systems save time and labor

✔ Customizable interiors to match modern living standards

7. Final Testing & Inspection of Expandable Container Houses

Before shipment, every expandable prefab home undergoes a multi-point inspection to guarantee functionality, safety, and ease of installation.

🔹 Process:

✔ Electrical and appliance functionality test

✔ Waterproof & wind resistance validation

✔ Final structural strength and expansion mechanism test

🔹 Global Compliance:

✔ Meets Australian, U.S., and EU modular housing regulations

✔ Designed for quick international shipping & installation

8. Secure Packaging & Shipping of Expandable Container Houses

After passing inspection, the expandable container homes are carefully packed and prepared for shipment.

🔹 Process:

✔ Wrapping all expandable parts in protective layers

✔ Packing multiple units into a 40ft high cube container for efficient transport

✔ Custom crating for high-value shipments

Conclusion: Why Choose Sunfine for Expandable Container Homes?

At Sunfine, we combine precision manufacturing, durable materials, and strict quality control to ensure our expandable container houses are built to the highest standards. Our factory-direct pricing and customization options make us the ideal partner for customers worldwide.

✔ ISO & CE-certified expandable homes

✔ Custom-built designs for any climate

✔ Fast global shipping & easy installation

📩 Interested in an expandable prefab home? Contact us today!

📧 Email: sfmodular@sfmodular.com

📞 Phone: +86 136 9696 2201