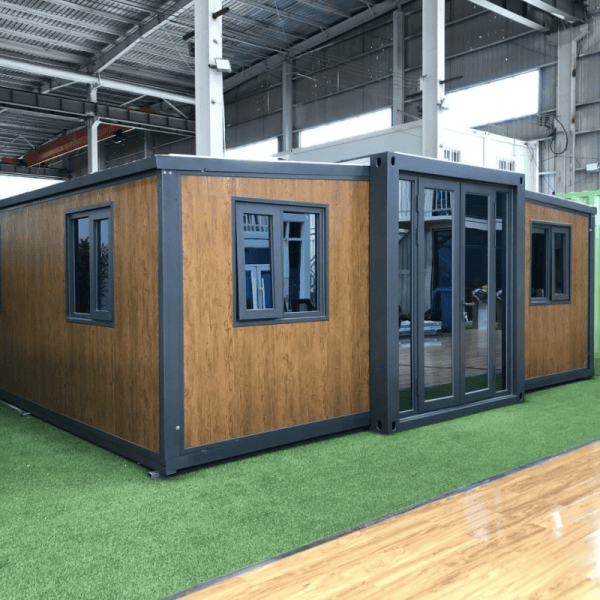

Production Process of Expandable Houses

Below, we outline the detailed manufacturing process, from material preparation to final packaging and shipment.

The expandable house is an innovative modular housing solution designed based on a standard 20ft container with expandable wings on both sides. This feature allows the home to be extended or retracted as needed, providing a larger living or workspace without compromising portability. To ensure exceptional quality and durability, the production process of these expandable container homes follows rigorous standards.

Cutting process

Cut materials according to the production order requirements.

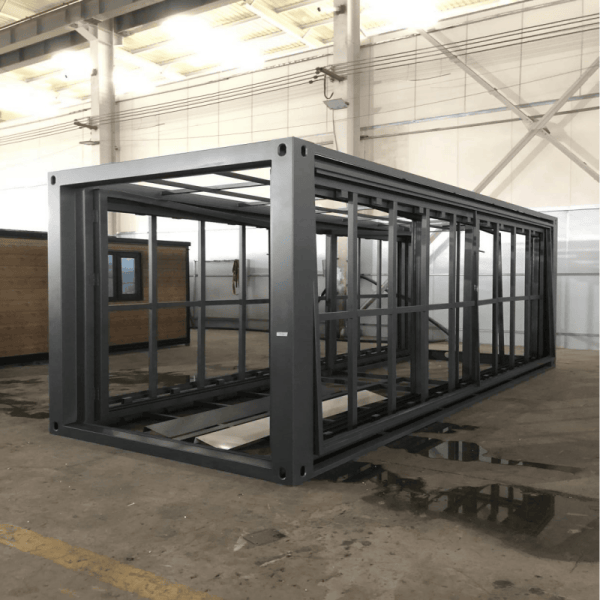

Welding process

Weld components in the workshop and polish them.

Frame assembly

Assemble the welded components into a complete frame and polish them.

Frame inspection

The quality inspector inspects the frame to ensure quality.

Finished product acceptance

After assembly, the quality inspector conducts final acceptance.

Plastic spraying process

Electrostatic spraying and baking paint are performed on the qualified frames.

Packing and warehousing

The finished products are cleaned and packed and stored in preparation for shipment.

Assembly process

Workers install floors, circuits, walls, doors and windows and other components to complete the overall assembly.